Polymer processing

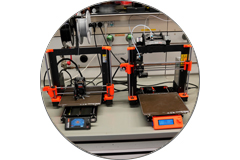

3D printing: FDM, Filament 1.75 mm

- Prusa MK4 with Prusa MMU3

- Prusa XL with 5 Extrudern

- Anisoprint Composer A4 endless carbon fiber

- Modix Big60 V4 Upgrade Dual-Extruder

Spin-coater (Convac 1001)

Evaporator (Balzers PLS500) with combinatory insert

The system has 3 effusion sources for organic materials and 2 resistance heaters for evaporating inorganic materials or metals. Linear or stepped layer gradients, defined material sectors or co-evaporated multi-material layers can be produced with the aid of the self-developed combinatorial turntable.

PFTE Ultra-thin film coater (Tribotrak, DACA)

With the Tribotrack, after heating a Teflon rod and a corresponding substrate to 200 – 300°C, the Teflon rod is pressed onto the substrate and then pulled over the hot substrate. A thin Teflon film is deposited which can be used, for example, as an orientation layer for liquid crystals or other anisotropic molecules.

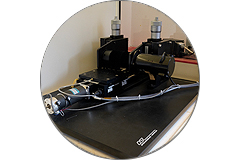

Buffing machine (Parker Positioning Systems Daedal Division)

With the aid of the bufffing machine, the surface molecules of a polymer film can be oriented by guiding the film past the rotating roller, which is covered with a velvet cloth, in light contact.

Rotary microtome Leica RM2255

With the Leica RM255 rotary microtome, sample sections can be prepared using the cutting mode (0 – 420 mm/s, section thickness: 0.5 – 100 µm) and the trimming mode (electric coarse drive, 300 or 800 µm/s, section thickness: 1 –600 µm).